First, don’t go to Wal-Mart, Target or Home depot to buy a step stool. The step stools they sell are just plain cheap and won’t hold a lot of weight.

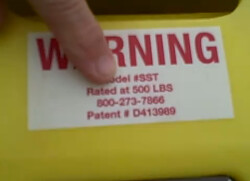

Very important: Next thing to do is look for a load rating on the step stool of 500 pounds. If the step stool you are looking at doesn’t have a load rating permanently attached to itself, it won’t hold a lot of weight. Period.

|  |  |

Don’t waste your time looking at step stools that have legs… Step stools that have legs cannot hold a lot of weight! Legs are dangerous because they will become bent, loose or make the step wobbly. Folding legs on a step stool are the first part to wear out. Legs will make the step stool unsafe for passenger use.

The other problem with legs on a step stool is that the bottom of the legs are used for the non-slip pads (if the step even has non-slip pads). The step stool usually has a rubber cap covering the tip of its metal legs, when the rubber wears through; the metal leg now slides on slick or wet surfaces.

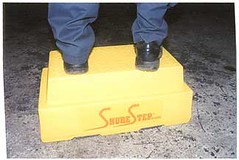

Look for a step stool with a solid design using a perimeter edge for the step stool to set on. Make sure the perimeter walls that support the step are at an angle, putting the weight of the person stepping on it, over the center of the step. This type of design also keeps the step stool from tipping over.

|  |  |

Do a Google search for safe step stool, aircraft step stool or heavy duty step stool to get a better idea of the best heavy duty step stools for aircraft passenger use.